safe operation of wind turbines. The primary goal of the control system is to optimize energy production, protect the turbine components, and ensure the safety of both the turbine and surrounding environment.

Wind Mill Control Systems are essential for the reliable and efficient operation of wind turbines, contributing to the overall effectiveness and sustainability of wind energy generation. The integration of advanced control strategies and technologies continues to evolve to meet the growing demands of the renewable energy industry.

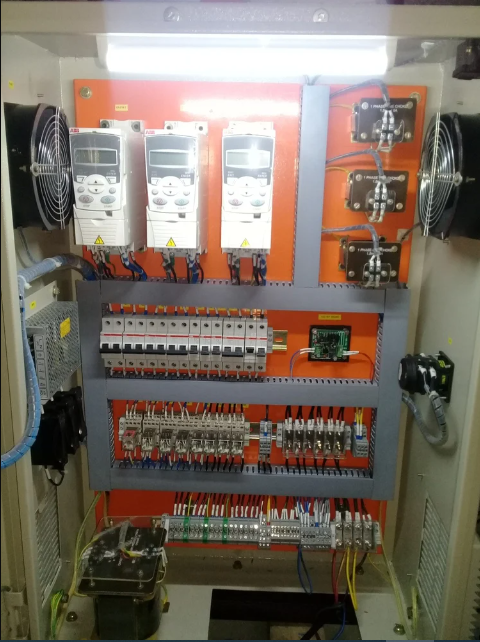

Have you ever wondered: what are all of the components that get installed into a PLC panel and why are they needed? Well you’re in luck! We will take a deeper look into the internal workings of a common PLC panel and its components…

Put simply, a PLC panel is a special steel box that contains electrical components required to run a factory machine or process. PLC stands for Programmable Logic Controller, an industrial hardened computer usually found inside factory control panels. High voltage components are what makes up a lot of the other items found inside. What are the other components? Let’s take a look at the two types of components:

A Motor Control Center (MCC) is an assembly that controls several or all-electric motors centrally. There are multiple enclosed sections and a common power bus. Each section has a combination starter, which consists of a motor starter, fuses or circuit breakers, and a power disconnect. It is also possible to equip a motor control center with push buttons, indicator lights, variable-frequency drives, programmable logic controllers, and metering equipment. In some buildings, it may be combined with the electrical service entrance.

Typically, Motor Control Centers can be found in large industrial or commercial buildings containing a lot of electrical motors that must be controlled centrally, such as an electrical room or mechanical room.

EURO PROCESS ACUTOMATIK – APFC (Automatic Power Factor Correction) & IPFC (Intelligent Power Factor Correction) Panels is an advanced product and it can achieve desired power factor under fluctuating load conditions in power plants, steel rolling mills this link, sugar plants, cement plants, chemical plant, dairy plants, Textile, sugar, Hospital, Automobile, and building segment, etc.

With the ever-rising cost of electricity, power management, and efficiency are essential for all organizations. Automatic Power Factor Correction or APFC panels are electrical control panels used for this purpose.

Being efficient, these panels maintain the power factor of an electrical system by automatically regulating the reactive power (kVAR) required by inductive loads. This reduces power loss, increases energy efficiency, and lowers electricity bills.

PMCC- Power cum Motor control Center panels are combination of Motor Control Center-MCC and Power Control Center-PCC panel.

The MCC Panels are used in industrial and commercial applications for connecting the individual motors for manually, remotely or automatically starting, stopping selecting forward and reverse rotation, selecting and regulating the speed, regulating and limiting the torque and protecting against overload, single phasing, phase imbalance, earth fault, under current, under / over voltage, lock rotor current, high winding temperature etc.

The PCC Panels are the most essential part of electrical system of an industry from where the power of the industry is controlled. PCC Panel is a power distribution board to control the Electrical power supplied to HT Panels, MCC panels and transformers who play vital role in all electrical control system.

Power Control Centre is used for distribution and control of various power source used in industry. Normally Power Control Centers is installed near power source hence fault level is high.

Power Control Centre is used for distribution and control of various power source used in industry. Normally Power Control Centers is installed near power source hence fault level is high.

Car Park Ventilation System Automation Panel is very important for both ventilation of car parks and smoke control. In order for the ventilation system to work actively and efficiently, reliable systems equipped with modern technology should be preferred. Today, mostly car parks are located in city centers and structures such as shopping centers, theaters, cinemas and business centers. In such car parks, systems for fighting smoke and fire during an emergency are vital for the safe evacuation of dense crowds and for the fire brigade to respond appropriately.

We are the authorized dealers of PLC for Water Treatment which is of optimum in its design and flexibility. Our PLC panels are designed as per end user requirement, and require minimizes human interface with machine, thus minimizes the possibility of error. The whole system can be monitored & controlled at single junction and set with data logging of all processes parameters with alarm. Its system set parameter can be changed as per end user requirement

Avail from us PLC panels for effluent treatment plants which are designed the automatic control of effluent treatment panels applicable for various industries. Our product is known for their custom made design based on the control and status with system lay out according to the demands of clients. Our PLC for effluent treatment plants are known for its efficiency, substantial energy saving, high-performance, rugged design with simple installation.

Euro Process Automatik is a reckoned name engaged in supplying a wide range of automation, process controls and energy savings systems like AC Drives, DC Drives, PLC (Programmable Logic Controller), Servo Drives,Machinery Drives, Control Panels, Automatic Power Factor Control Panels,etc.

Address

Euro Process Automatik

250 C, 10th st, North Phase,

Sector ||, Sidco Industrial Estate, Ambattur, Chennai, Tamil Nadu 600098 India

© 2024 | Euro Process Automatik. All rights reserved

Design & development by SALES UPGRADE